Three-Axis Horizontal Turn Positioner / Welding Robot Positioner

Technical Parameters

|

Vertical Turnover Triaxial Servo Positioner |

Horizontal Rotary Triaxial Servo Positioner |

||||||

|

Serial number |

PROJECTS |

Parameter |

Parameter |

REMARKS |

Parameter |

Parameter |

REMARKS |

|

1 |

Rated load |

500kg |

1000kg |

Within R400mm radius of the second axis |

500kg |

1000kg |

Within R400mm/R500mm radius of the second axis |

|

2 |

Standard gyration radius of spindle |

R1200mm |

R1500mm |

R1200mm |

R1800mm |

||

|

3 |

Standard gyration radius of countershaft |

R400mm |

R500mm |

R400mm |

R500mm |

||

|

4 |

First axis flip angle |

±180° |

±180° |

±180° |

±180° |

||

|

5 |

Second axis rotation angle |

±360° |

±360° |

±360° |

±360° |

||

|

6 |

Rated upturn speed of first axis |

50°/S |

24°/S |

50°/S |

24°/S |

||

|

7 |

Rated rotating speed ofsecond axis |

70°/S |

70°/S |

70°/S |

70°/S |

||

|

8 |

Repeat positioning accuracy |

±0.10mm |

±0.20mm |

±0.10mm |

±0.20mm |

||

|

9 |

Boundary dimension of displacement frame (length×width×height) |

2200mm×800mm ×90mm |

3200mm×1000mm ×110mm |

2200mm×800mm ×90mm |

3200mm×1000mm ×110mm |

||

|

10 |

Overall dimension of position shifter (length×width×height) |

4000mm×700mm ×1650mm |

5200mm×1000mm ×1850mm |

4000mm×700mm ×1650mm |

4500mm×3600mm ×1750mm |

||

|

11 |

Center height of the first axis rotation |

1350mm |

1500mm |

800mm |

1000mm |

||

|

12 |

Power supply conditions |

Three-phase 200V±10%50HZ |

Three-phase 200V±10%50HZ |

Three-phase 200V±10%50HZ |

Three-phase 200V±10%50HZ |

With isolation transformer |

|

|

13 |

Insulation class |

H |

H |

H |

H |

||

|

14 |

Net weight of equipment |

About 1800kg |

About 3000kg |

About 2000kg |

About 2000kg |

||

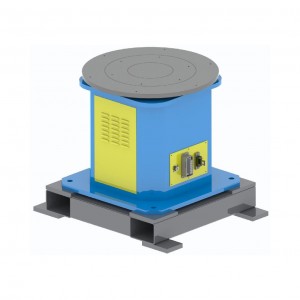

Horizontal Rotary Triaxial Servo Positioner

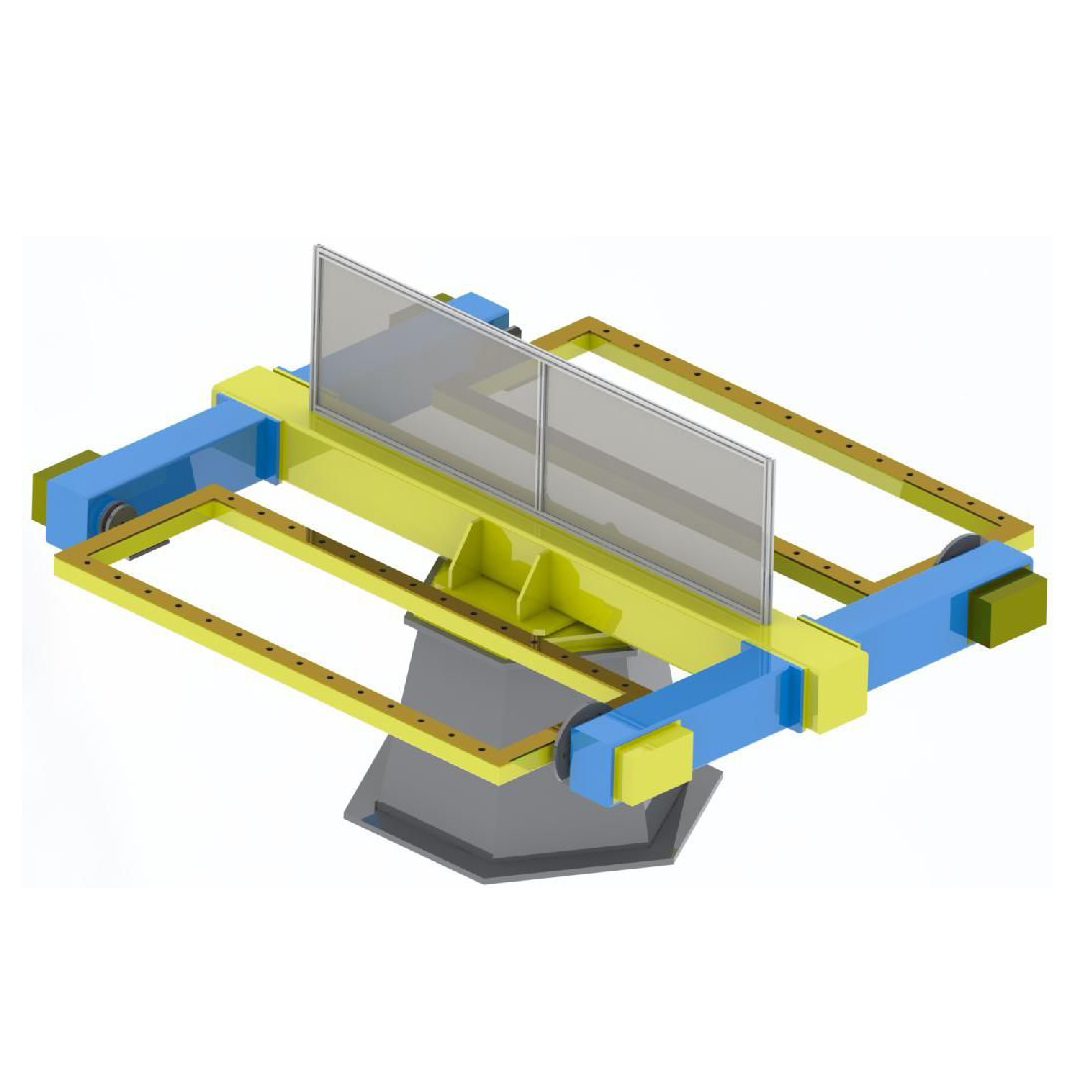

Vertical Turnover Triaxial Servo Positioner

Structure Introduction

The triaxial vertical turnover servo positioner is mainly composed of welded integral frame, turnover displacement frame, AC servo motor and RV precision reducer, rotary support, conductive mechanism, protective shield and electrical control system.

The welded integral frame is welded with high-quality profiles. After annealing and stress relieving, it shall be processed by professional machining to ensure high machining accuracy and accuracy of key positions. The surface is sprayed with anti-rust appearance paint, which is beautiful and generous, and the color can be customized according to customer requirements.

Turnover displacement frame shall be welded with high-quality profile steel and processed by professional machining. The surface shall be machined with standard threaded holes for mounting positioning tooling, and painting and blackening and rust prevention treatment shall be carried out.

AC servo motor with RV reducer is selected as the power mechanism, which can ensure the stability of rotation, accuracy of positioning and

Long durability and low failure rate. The conductive mechanism is made of brass, which has a good conductive effect. The conductive base adopts integral insulation, which can effectively protect servo motor, robot and welding power source.

The electric control system adopts Japanese Omron PLC to control the positioner, with stable performance and low failure rate. The electrical components are selected from famous brands at home and abroad to ensure the quality and stability of use.

Light blocking shield is assembled with aluminum profile and aluminum plastic plate to protect against arc light generated during welding and cutting.