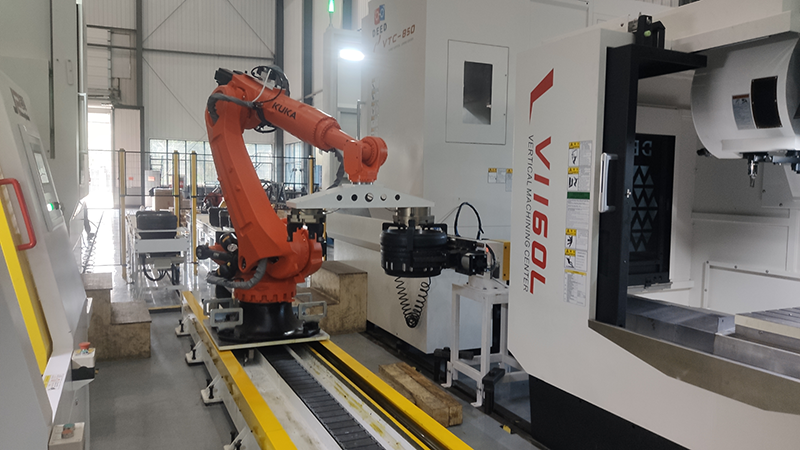

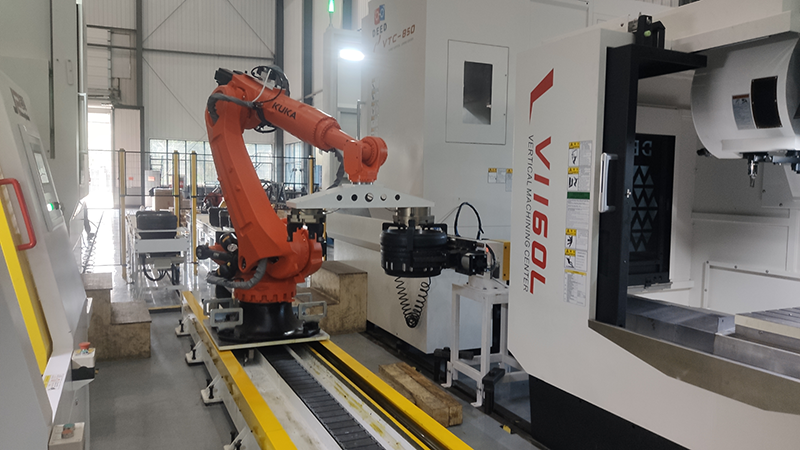

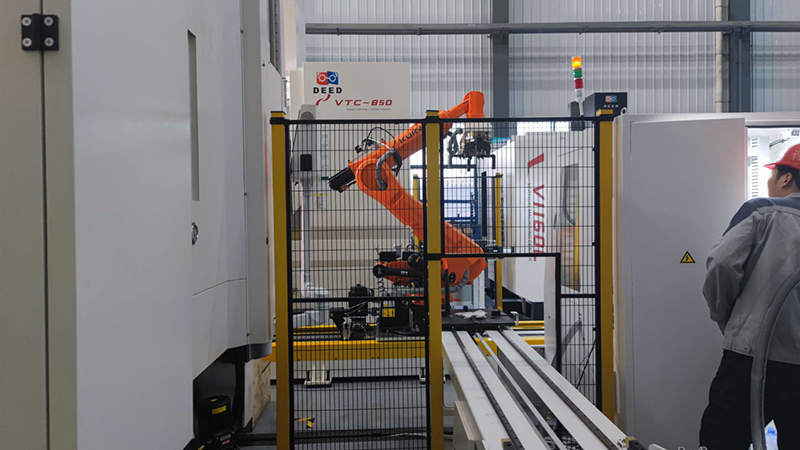

The case I want to share with you today is the loading and unloading workstation of the brake drum machine tool. This project adopts a handling robot, taking materials from the feeding roller line, setting up the car, turn over, adding the loading and unloading of the machine tool, and cleaning the unloading after dynamic balance detection.

The project difficulty, the weight of the workpiece is relatively large, the processing accuracy requirement is high, the vertical car and the vertical processing position is different, resulting in the different direction of the clip, the need to turn, the processing surface requires no iron chips.

Highlight of the project, the loading and unloading conveying lines are controlled by sections, which can increase the cache and prevent the collision of the processed workpiece from affecting the surface processing quality. The robot grip adopts the double position three claws inside and outside clip, and the turning two claws outside clip, which can not only realize the loading and unloading of the car, but also ensure the accuracy of loading and unloading. Add high pressure ring blowing air to solve the residual iron filings and cutting fluid on the surface of the workpiece.

Post time: Dec-18-2023