CR Series Flexible Cooperative Robot

Technical Parameters

|

CR7 |

CR12 |

|||

|

Specification |

||||

|

Load |

7kg |

12kg |

||

|

Working radius |

850mm |

1300mm |

||

|

Dead weight |

Approx. 24kg |

Approx. 40kg |

||

|

Degree of Freedom |

6 rotary joints |

6 rotary joints |

||

|

MTBF |

>50000h |

>50000h |

||

|

Power supply |

DC 48V |

DC 48V |

||

|

Programming |

Drag teaching and graphical interface |

Drag teaching and graphical interface |

||

|

Performance |

||||

|

POWER CONSUMPTION

|

Average |

Peak

|

Average |

Peak

|

|

500w |

1500w |

600w |

2000w |

|

|

Safety Certification |

>22 Adjustable Safety Functions Comply with “EN ISO 13849-1, Cat. 3, PLd, EU CE Certification” Standard |

>22 Adjustable Safety Functions Comply with “EN ISO 13849-1, Cat. 3, PLd, EU CE Certification” Standard |

||

|

Force sensing, tool flange |

Force, x-y-Z |

Moment of force, x-y-z |

Force, x-y-Z |

Moment of force, x-y-z |

|

Resolution ratio of force measurement |

0.1N |

0 02Nm |

0 1N |

0.02Nm |

|

Relative accuracy of force control |

0 5N |

0 1Nm |

0 5N |

0 1Nm |

|

Adjustable range of Cartesian stiffness |

0~3000N/m, 0~300Nm/rad |

0~3000N/m, 0~300Nm/rad |

||

|

Range of operating temperature |

0~45℃ |

0~45℃ |

||

|

Humidity |

20-80%RH (non-condensing) |

20-80%RH (non-condensing) |

||

|

Motion |

||||

|

Repeatability |

±0.02 mm |

±0.02mm |

||

|

Motor joint |

Scope of work |

Maximum speed |

Scope of work |

Maximum speed |

|

Axis 1 |

±180° |

180°/s |

±180° |

120°/s |

|

Axis 2 |

±180° |

180°/s |

±180° |

120°/s |

|

Axis 3 |

±180° |

234°/s |

±180° |

180°/s |

|

Axis 4 |

±180° |

240°/s |

±180° |

234°/s |

|

Axis 5 |

±180° |

240°/s |

±180° |

240°/s |

|

Axis 6 |

±180° |

300°/s |

±180° |

240°/s |

|

Axis 7 |

----- |

----- |

----- |

----- |

|

Maximum speed at tool end |

≤3.2m/s |

≤3.5m/s |

||

|

Features |

||||

|

IP Protection grade |

IP67 |

IP67 |

||

|

ISO Clean Room Class |

5 |

5 |

||

|

Noise |

≤70dB(A) |

≤70dB(A) |

||

|

Robot mounting |

Formal-mounted, inverted-mounted, side-mounted |

Formal-mounted, inverted-mounted, side-mounted |

||

|

General-Purpose I/O Port |

Digital Input |

4 |

Digital Input |

4 |

|

Digital Output |

4 |

Digital Output |

4 |

|

|

Security I/O Port |

External emergency |

2 |

External emergency stop |

2 |

|

External safety door |

2 |

External safety door |

2 |

|

|

Tool Connector Type |

M8 |

M8 |

||

|

Tool I/O Power Supply |

24V/1A |

24V/1A |

||

Product Application

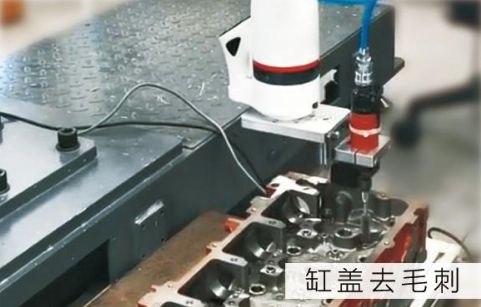

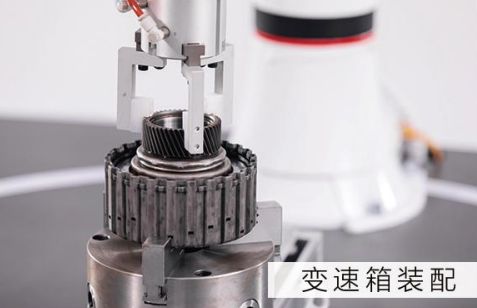

And the parts industry is an industry with high automation level, but there are still huge incremental opportunities throughout the supply chain. If the general assembly process is relatively complicated and the process flexibility is high, the safer and more flexible cooperative robot can cope with various complicated processes and working conditions and is gradually replacing the traditional industrial robots, adding value for many production stages in automobile manufacturing and improving the overall production efficiency.

Automotive industry has strict standards and complete system, and users pay attention to the quality and consistency of repeated tasks, so the cost-effective and high efficient collaborative robot is the ideal choice. The exMate flexible collaborative robots are easy to install and redeploy, which meets the needs of the automotive industry for customization and rapid response to changing markets. The leading security ensures the safety of operators while improving the efficiency and makes man-machine coexistence and collaborative working a reality.