Automatic Rotary Loading/Unloading Bin / Machine Tool Loading/Unloading Bin

Product Application Scheme

Technical scheme of machine tool loading and blanking flange project

Project Overview:

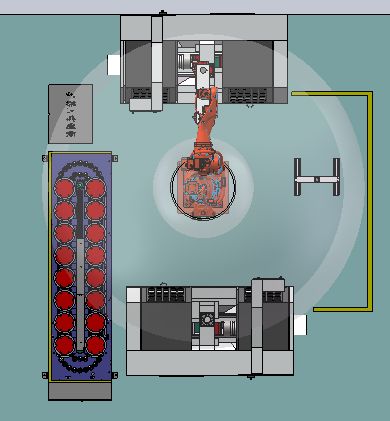

According to the workstation flow for process design of the user’s round flanges, this scheme adopts one horizontal NC lathe, one horizontal turning-milling composite center, one set of CROBOTP RA22-80 robot with one set of clutches, one robot base, one loading and blanking machine, one roll-over table and one set of safety fence.

Project Design Basis

Loading and blanking objects: Round flanges

Appearance of the workpiece: As shown in the figure below

Individual Product Weight: ≤10kg。

Size: Diameter ≤250mm, thickness ≤22mm, material 304 stainless steel, technical requirements: Load and blank the machine tool according to the round flange processing card, and has the functions such as accurate grasping of material by robot and no falling during power failure.

Working system: Two shifts per day, eight hours per shift.

Scheme Layout

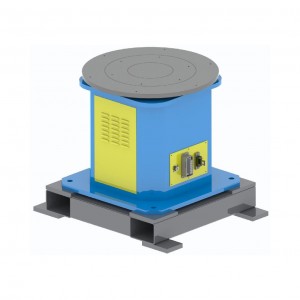

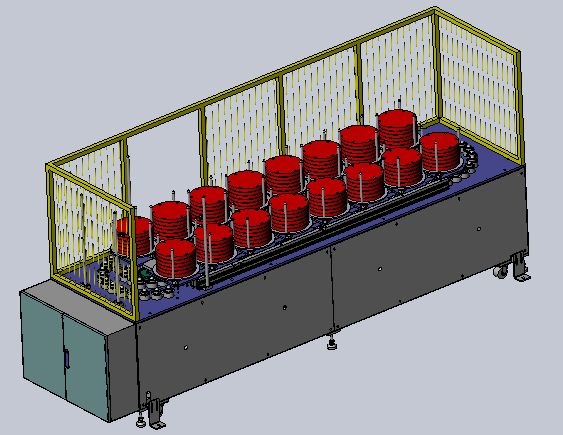

Required silo: Automatic rotary loading and blanking silo

Full-automatic rotary mode is adopted for the loading/blanking silo. Workers load and blank at the side with protection and the robot works on the other side. There are totally 16 stations, and each station can accommodate 6 workpieces at most.