Automatic Feed Pallet Bin / Palletizing Cooperative Bin / Automatic Loading And Unloading

Product Application Scheme

Technical scheme for double-ring buckle machining and loading and blanking project

Project Overview:

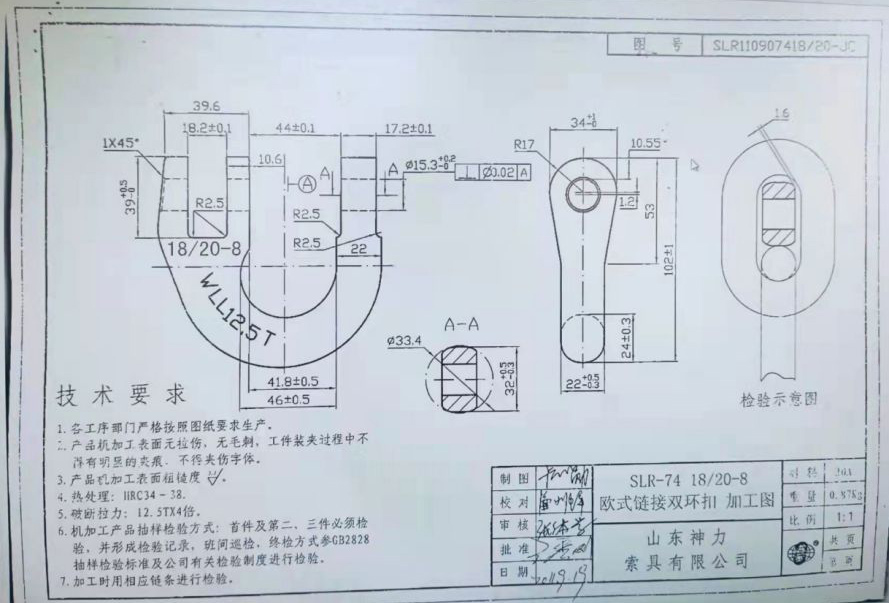

Workpiece Drawings 1

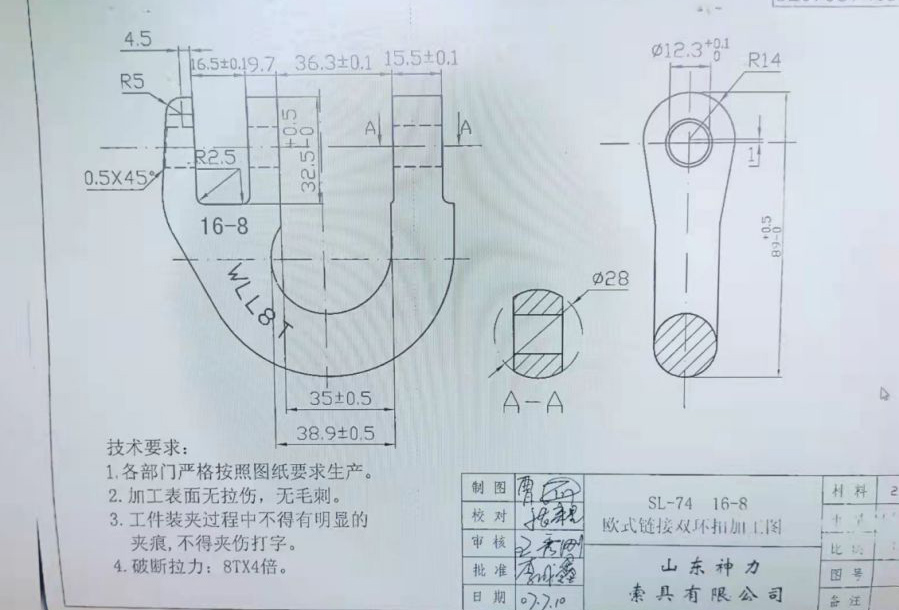

Workpiece Drawings 2

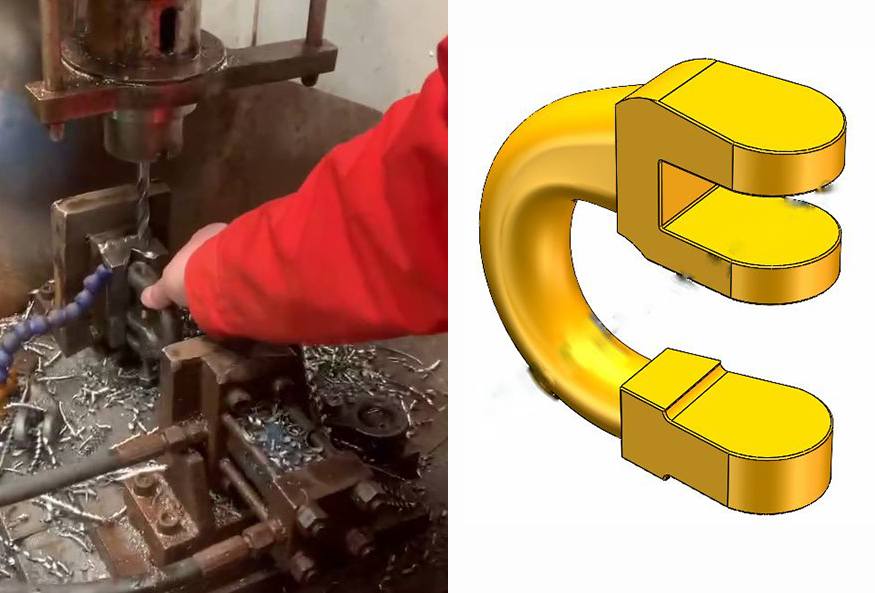

Real picture &3D model of the workpiece

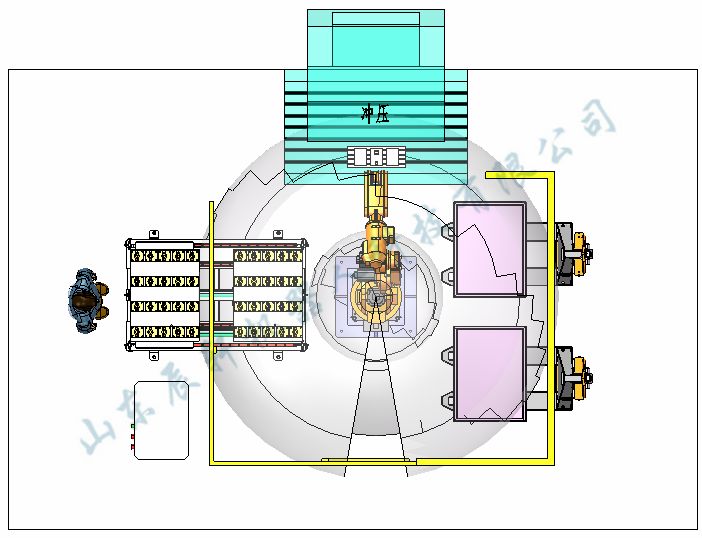

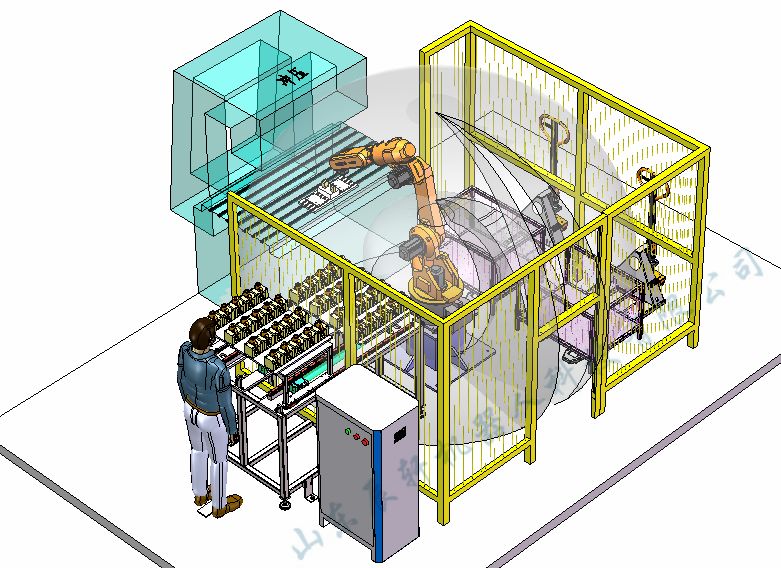

Scheme Layout

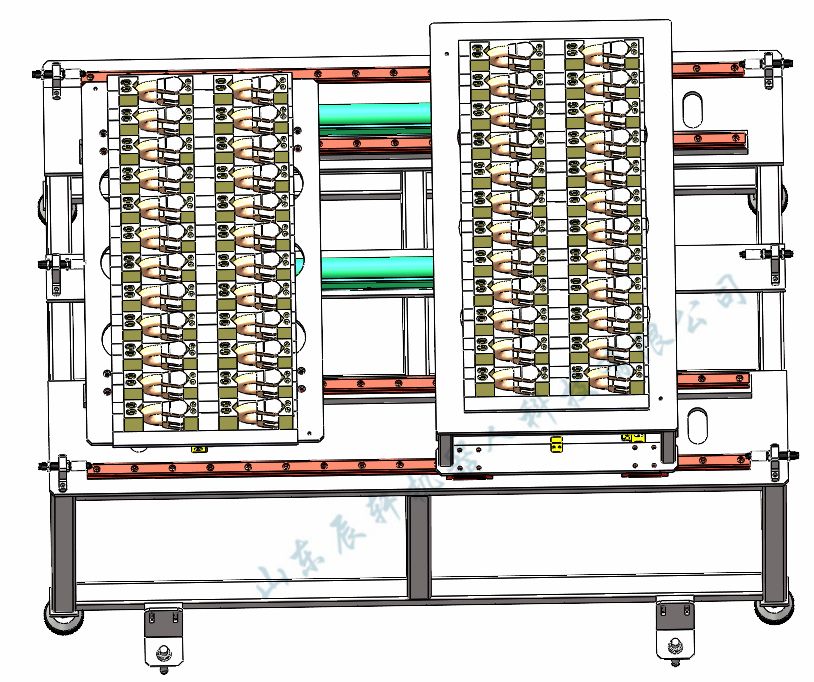

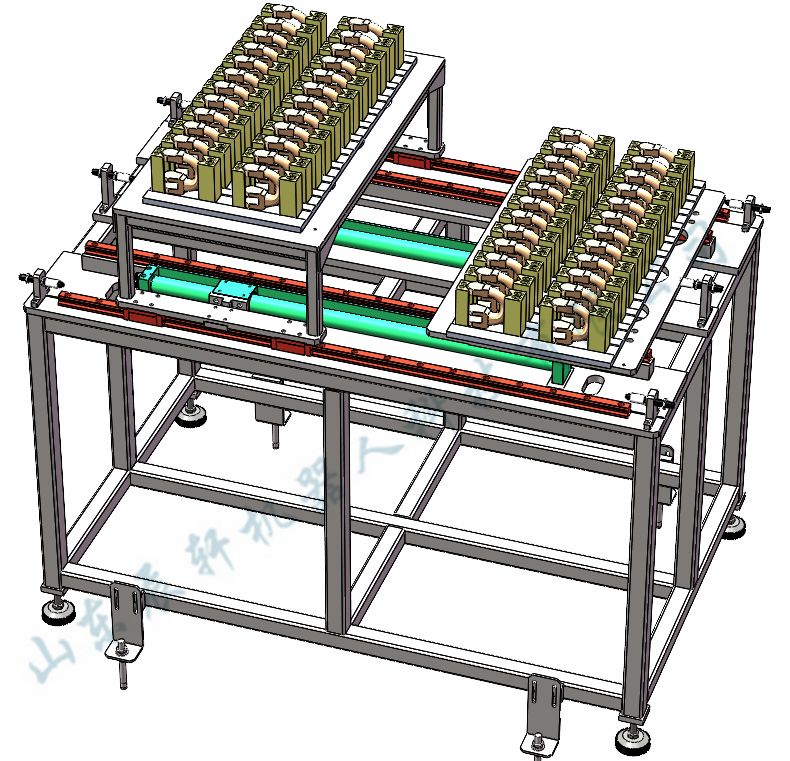

Loading silo:

1. The loading silo adopts upper and lower layer structure, saving more space and providing larger storage capacity and high cost performance;

2. About 48 products can be placed in the preliminary design. Under the condition of regular manual feeding every 50 minutes, the operation without shutdown can be realized;

3. The material tray is error-proofed, to assist manual convenient emptying, and silo tooling for workpieces of different specifications shall be adjusted manually;

4. The specification of materials stored in silo can be customized according to site equipment parameters and user requirements;

4. Oil and water resistant, anti-friction and high-strength materials are selected for the feeding tray of the silo, and manual adjustment is required when producing different products;

7. The diagram is for reference only, and the details shall be subject to the actual design.

Service

To greatly enhance the quality of the products and reduce the production cost through technical innovation, process improvement, introduction of advanced equipment and technology and elimination of outdated technology and production line.

To reduce the cost of each process from production to the customer in the trade chain and thus provide customers with products with competitive price.

To save every penny for customers by promoting the standardization and normalization of production and trade management process while reducing the hidden costs caused by possible misunderstanding.